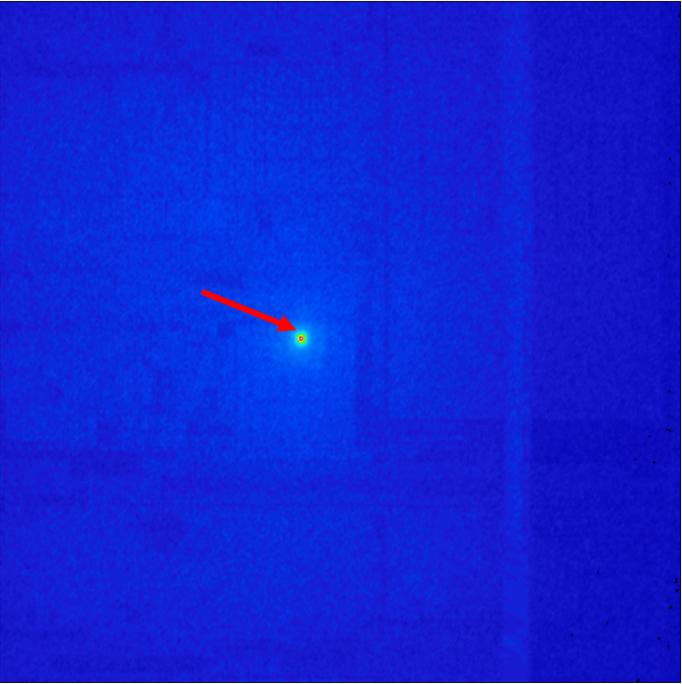

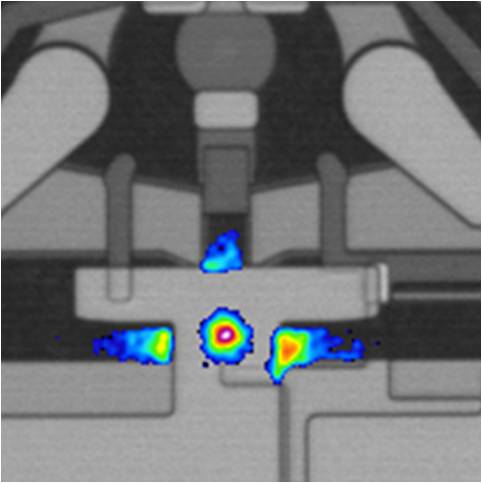

A traditional approach to finding shorts in semiconductor devices has been liquid crystal investigation. Unfortunately, liquid crystal investigations have several limitations: low sensitivity (especially from the backside), slow response, operator exposure to bio-hazardous materials, difficulties with application and interpretation. QFI’s Thermal-HS medium wave infrared (MWIR) hot spot sensor locates ohmic faults from their self-heating. Heat radiates in the infrared spectral range, and the QFI’s MWIR sensors are capable of capturing these radiant emissions. Custom objective lenses made with infrared transmissive materials such as silicon, germanium, sapphire, and zinc selenide complete the optical path between DUT and sensor. Silicon is transparent in the MWIR and heat-generating defects emit in an isotropic manner. Therefore, the hot spot sensors work well in front side and backside applications. The Thermal-HS solution incorporates unique application software and calibrations to maximize hot spot detection sensitivity. Thermal-HS is available with a 1024×1024 MWIR sensor for the highest pixel resolution available in an infrared hot spot detection system. QFI has been the world’s leading supplier of infrared hot spot detection systems for many years. The Thermal-HS solution can detect a broader range of defects than liquid crystal, and does so with much greater ease-of-use and sensitivity. QFI offers steady-state hot spot detection, as well as several dynamic techniques for hot spot detection.